The term “Shock Physics” is not defined in traditional dictionaries or even in our modern-day Wikipedia. This expression, which originated in the English language, refers to a specific branch of Physics that studies the behaviour of materials subjected to impacts and the behaviour of explosives. The latter is also sometimes referred to as “detonics”.

How to classify Shock Physics?

Physics can be divided into several major branches such as optics, mechanics, electromagnetism, thermodynamics and more recent branches including general relativity or quantum mechanics. The distinguishing feature of each of these branches is the type of material behaviour they are concerned with, and consequently, the various laws that govern that behaviour. Shock Physics is part of Classical Mechanics, in which laws can be expressed as mathematical equations and describe the conservation of certain values such as mass, energy and momentum. The purpose of these general laws of mechanics is to explain how materials move when subjected to mechanical forces. More generally, mechanical engineers provide answers to the question “how does a material change shape depending on the forces (or stresses) applied to it?” If we were to give a very general summary, we could say that mechanics is concerned with the way materials are deformed when subjected to forces.

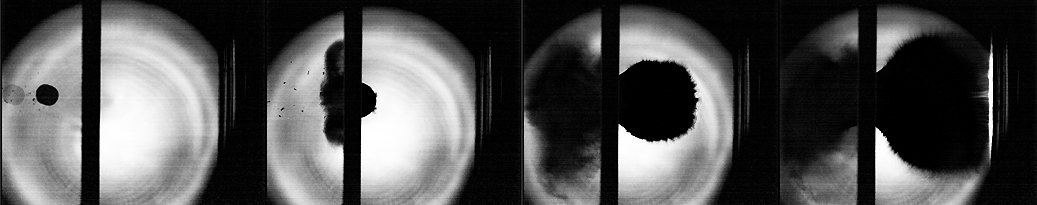

ball impact on aluminum plate, 8600 m/s

Characteristics of Shock Physics

Shock Physics is concerned with the same phenomena, but with one fundamental difference: the time during which the stress is applied (force per unit area). In other words, in the case of an impact (vehicle against a wall, block of ice on an aircraft cockpit, bullet on armour, space debris on a satellite, etc.) or explosive, the material is subjected to shock waves which transmit information about the stress imposed on a part of the material. The propagation times are relatively short, depending on the propagation speed of the shock waves within these materials. For example, in steel or aluminium, the propagation time (also known as velocity of propagation) is around 5,000 m/s, in ceramics approximately 10,000 m/s and in plastics around 3,000 m/s.

The main characteristic of Shock Physics is therefore the dynamics of the phenomena encountered, i.e. the speed at which the material is deformed. The time scales dealt with here are microseconds (µs = one millionth of a second) or even nanoseconds (ns = one billionth of a second). No need to be a genius to work out that a material will not react in the same way if it is subjected to forces for one µs or several seconds.

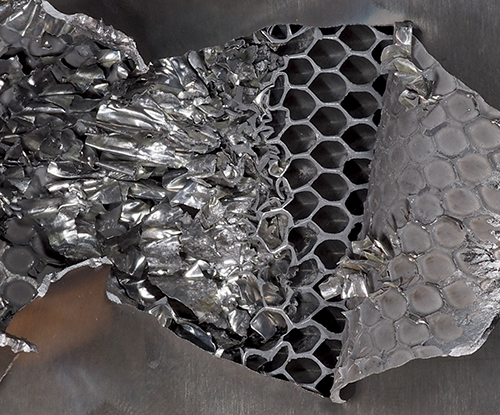

This is the real crux of Shock Physics: how to characterise a material’s behaviour (deformation, damage, fragmentation) with respect to the intensity of the stress applied as well as the time during which it is applied.

Detail of Nida material after impact.

Diverse fields of application

This branch of Physics is applied in the following major fields:

- Defence & Security (bullet impacts, explosions)

- Aerospace (bird strikes, hail, etc.)

- Space (space debris, vulnerability of spacecraft and satellites)

- Energy (oil and mining exploration)

- Geophysics (Earth’s behaviour, asteroid impact events)

- Astrophysics (behaviour of planets and stars)

- Materials engineering (creation of new materials, transformation of graphite into diamond)

Advantages of digital simulation

As regards calculations, specific software applications are used to simulate these rapid phenomena and offer various resolution algorithms. These algorithms or digital diagrams are selected according to the configuration being studied. The main difficulty related to the use of this software is the fact that the behaviour encountered is non-linear. This non-linearity leads to major deformations of the material, corresponding to phenomena that push the boundaries of the equations which these digital diagrams are able to validate. Consequently, the Shock Physics software currently available is not sufficiently reliable to eliminate the need for validation tests.

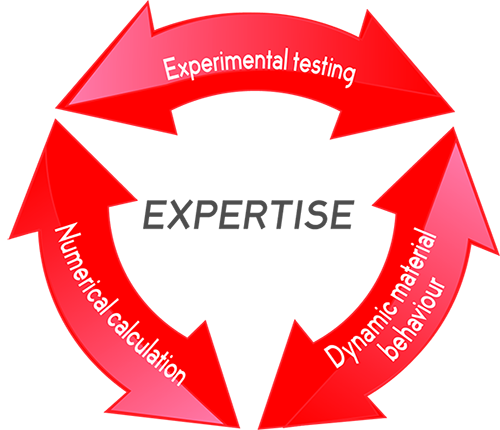

To sum up, the powerful combination of calculations, characterisation of dynamic behaviour and testing (not forgetting the contribution of metrology) guarantees that the results obtained by Thiot Ingenierie’s experts are sufficiently reliable.